High-Barrier, Food-Grade & Print-Ready Custom Pouch Bags for Modern Brands

Custom Flexible Packaging Solutions

Our custom pouch bags are engineered for durability, barrier protection, retail-ready aesthetics, and production stability.

Whether you’re packaging food, coffee, cosmetics, supplements, pharmaceuticals, or household products, we deliver fully tailored flexible packaging solutions with low MOQ and fast sampling.

Why Custom Pouch Bags Matter

Your packaging is more than protection — it’s your first impression. A well-designed gift box communicates:

Luxury & Quality

Premium materials, perfect finishing, and brand alignment.

Differentiation

Unique structures and colors that stand out on crowded shelves.

Sustainability

Recyclable materials and eco-conscious printing to meet global standards.

Brand Storytelling

ackaging that emotionally connects with your audience before they even open it.

Our Custom Pouch Bag Capabilities

We provide end-to-end pouch bag development from structure design to final printing and assembly.

Food-grade, FDA-compliant materials

·FDA 21 CFR Food Contact Standards

·EU 10/2011 Plastic Food Contact Regulation

·LFGB German Food Safety Regulations

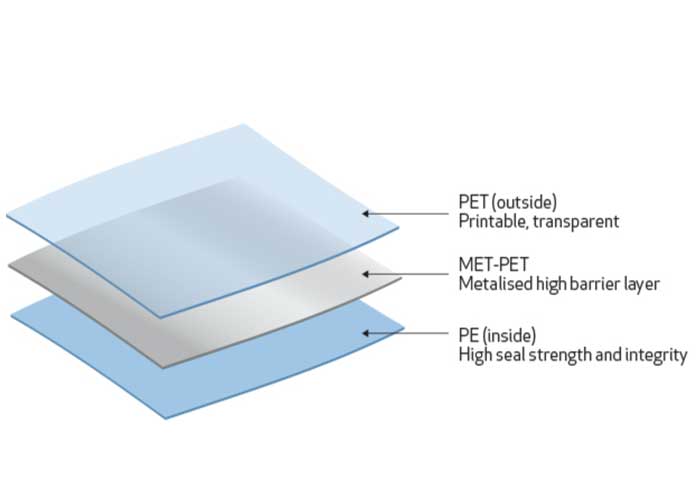

High-barrier performance

·PET/AL/PE - Ultra High Barrier

·PET/MET-PET/PE - resistant to light and oxygen, economically efficient

·Kraft/PET/AL/PE - Environmentally friendly appearance+high barrier

·Nylon/PE - puncture and stretch resistant

Stable standing structure

·Doypack curved bottom (most common, strong standing ability)

·K-seal bottom (stronger load-bearing capacity)

·Plow Bottom (Large Capacity Product)

Digital / Gravure Printing

·No version fee → Reduce startup costs

·Vibrant colors, suitable for complex designs

·Quick prototyping (2-3 days)

·Suitable for testing promotional, limited edition, and e-commerce bestsellers

Recyclable Mono-Material

·Simple structure, easy to recycle

·No aluminum layer → More environmentally friendly

·Can replace traditional PET/AL/PE composite structures (more environmentally friendly)

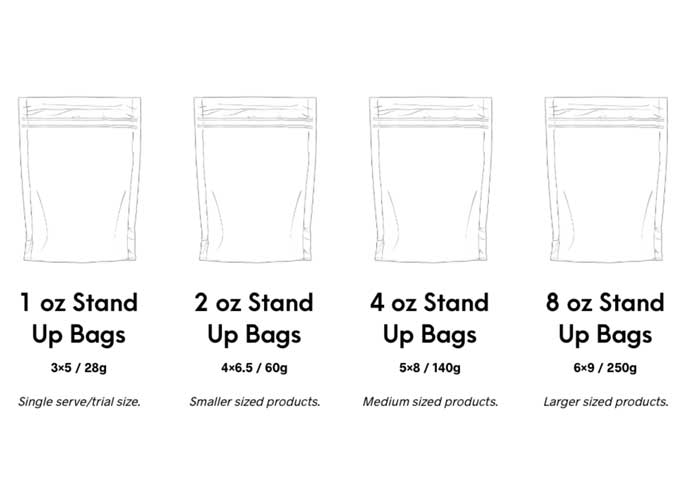

Custom Pouch Bag Options

1. Stand-Up Pouch (Doypack)

2. Flat Pouch

3. Zipper Resealable Pouch

4. Aluminum Foil Pouch

5. Kraft Paper Pouch

6. Three-Side Seal Pouch

7. Spout Pouch

Material Options

High-Performance Laminated Materials

We engineer multi-layer materials to achieve specific shelf-life and barrier properties.

| Material | Features | Ideal For |

| PET/PE | Strong, clear, high durability | Food, snacks, coffee |

| BOPP/CPP | High clarity, good sealing | Snacks, nuts, biscuits |

| PET/AL/PE | Light & oxygen barrier | Coffee, supplements |

| Kraft/PET/PE | Eco + durable | Tea, handmade goods |

| Mono-material PE | 100% recyclable | Sustainable packaging projects |

Barrier Options:

High barrier / medium barrier / moisture-proof / oxygen-block / UV-resistant / aroma-protection.

Premium Packaging Decoration for Brand Impact

We help brands bring their artwork to life with high-end printing technologies:

Printing Methods

·Digital Printing — Best for small MOQ, color-intensive designs

·Gravure Printing — For long-run, consistent, high-speed production

·Flexo Printing — Cost-friendly, fast delivery

Decoration Options

·Matte / gloss lamination ·Soft-touch feeling ·Metallic effect ·Window design ·Spot UV ·Foil stamping for pouch printing / custom pouch design to help brands bring their artwork

Application

Food & Snacks

Dried fruits, nuts, cookies, spices, freeze-dried foods.

Requirements addressed:freshness lock, moisture barrier, strong seals.

Coffee & Tea

High-barrier aluminum options + degassing valves.

Requirements addressed:aroma preservation, shelf-life.

Cosmetics & Skincare

Mask pouches, serum sachets, powder refill bags.

Requirements addressed:liquid resistance, precise sealing.

Supplements & Nutrition

Protein powder, vitamins, capsules.

Requirements addressed:light & oxygen barrier, tamper resistance.

Pharmaceutical Packaging

Medical powders, herbal products.

Requirements addressed:safety, compliant materials.

Household & Cleaning Products

Detergent, dishwasher pods, liquid refill bags.

Requirements addressed:puncture resistance, strong sealing.

Why Choose Anitarpak

Where We Build Your Visions

· Concept & Design Consultation

Share your ideas or send product samples.

· 3D Mockup & Structure Drafting

Visualize the box before production.

· Material & Color Sampling

Choose from 100+ paper and coating options.

· Prototype Creation

Receive a physical sample for approval.

· Mass Production & Printing

Fully automated cutting and assembly.

Sample Request

Please send us your design drawings to start the sample process

Learn More From

Get a Free Sample Quote

Size, material, quantity, application.

2.We Recommend Material & Structure

Optimized for barrier performance, cost and product category.

3.Artwork Confirmation

Template + print-proof + mock-up.

4.Sample Production

Digital sample or real production sample (3–7 days).

5.Mass Production

12–18 days depending on printing.

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 3-7 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.