Safe, Precise, and Compliant Packaging for Healthcare and Pharmaceutical Products

Medical & Pharmaceutical Packaging Solutions

The packaging in the pharmaceutical industry is not only the “outer packaging”, but also a part of supply chain security. We focus on providing high reliability packaging solutions that comply with FDA, EU, ISO standards for drugs, medical devices, nutritional supplements, topical preparations, and more

Industry Challenges

The pharmaceutical and medical device industry belongs to the highly regulated, high-risk, and high-precision fields, with much higher packaging requirements than ordinary consumer goods. Enterprises generally face the following challenges:

Compliance pressure and strict review

Compliance requirements such as FDA/EU/ISO are frequently updated, and materials must be low migration, non-toxic, and traceable.

The product has strong sensitivity and requires high barrier materials

Medicines are easily affected by humidity, oxygen, and light pollution, and packaging must have long-term stable protective performance.

The printing accuracy requirement is extremely high, with zero fault tolerance

Batch number, barcode, production date, and expiration date must be clear and readable, and printing deviation is not allowed.

Packaging must be compatible with sterilization processes

EO, Gamma, Autoclave high-temperature sterilization require different structural adaptations.

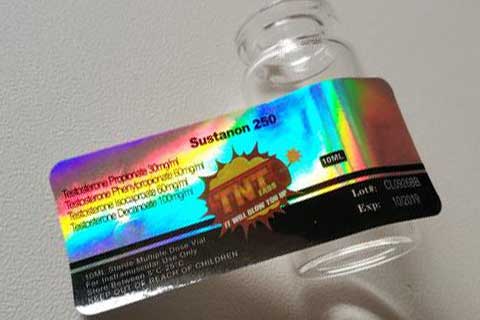

Risk of counterfeit goods and increased traceability requirements

Require anti-counterfeiting, tamper proof design, and traceable coding system

Industry Applications

Prescription & OTC Medicine

Packaging and labeling of tablets, capsules, oral liquids, powders, reagent bottles, etc.

Medical Devices

Sterilization bag, operation manual bag, instrument component packaging bag.

Diagnostics & Laboratory

Reagent bags, sampling bags, sealed bags, PCR consumables outsourcing.

Nutritional Supplements

Pharmaceutical grade labels, barrier bags, paper boxes, single dose packaging.

Disinfectant & First Aid

Chemical resistant labels, PET anti-corrosion labels, instruction paper boxes.

Available Custom Solutions

We provide one-stop pharmaceutical packaging solutions for pharmaceutical factories, medical device factories, and nutritional supplement brands, ensuring systematic guarantee from materials → printing → anti-counterfeiting → structure → compliance → sterilization → delivery time.

Pharma grade Materials

·Food/pharmaceutical grade composite film ·Low migration ink, BPA free, no heavy metals ·FDA/EU/RoHS/Reach Compliance ·Can be used for powders, tablets, freeze-dried

High barrier protection system

·Oxygen blocking, moisture blocking, light blocking ·Aluminum foil structure can achieve long-term preservation ·Maintain efficacy and reduce loss of active ingredients

Security & Tamper surveillance system

·Anti disassembly incision ·Invisible ink, UV marking ·One item one code tracking system (serial number/batch number)

Precision Printing (High Precision Printing System)

·Food/pharmaceutical grade composite film ·Low migration ink, BPA free, no heavy metals ·FDA/EU/RoHS/Reach Compliance ·Can be used for powders, tablets, freeze-dried

Sterilization compatible structures

·Suitable for EO, Gamma, 121 ° C steam sterilization ·Composite structure of medical dialysis paper ·Special film material for medical device bags

Sterilization compatible structures

·Mono material, single material ·Easy to recycle paper box ·Water based environmentally friendly ink

Recommended Products

Medical & Pharma Pouch Bags

Suitable for packaging powders, freeze-dried powders, liquid reagents, and small samples.

Pharmaceutical Labels

Cold chain labels, moisture-proof labels, anti-counterfeiting labels, tamper proof labels, high-precision batch/barcode/serial code printing

Pharma Paper Boxes

Folding box, box cover, partition structure, food grade ink, small batch sampling 24-48 hours

Medical Document Paper Bags

Instruction manual storage bag, prescription bag, medical equipment document bag

Other related customized medical packaging services

1. Certified Materials

HDPE / LDPE

Durable, lightweight, and chemically resistant.

PE

Ideal for liquid syrups and oral suspensions.

Amber PET

Transparent and UV-blocking for light-sensitive products.

Glass Bottles

Excellent for injectables, drops, and diagnostic liquids.

2. Functional Safety Designs

caps & seals

Child-Resistant Caps (CRC) and tamper-evident seals for safety compliance.

Dropper & Sprayer

Dropper bottles, syrup bottles, and nasal spray containers for precision delivery.

closures

Moisture-barrier closures to preserve powder or tablet integrity.

measuring

Optional measuring cups, droppers, or oral dispensers for user convenience.

3. Cleanroom Production & Quality Assurance

HEPA filtration and dust-free molding areas

100% visual inspection before packaging

Batch traceability and sterilization options

6 Steps To Copperate

01.

Requirements Analysis

Confirmation of product type, barrier requirements, sterilization method, and regulatory requirements.

02.

Material & Structure Proposal

Recommend film/paper/label structure and printing scheme.

03.

Artwork Engineering

File inspection, layout proofreading, and error proofing system review.

04.

Sample Production

Free standard samples/paid customized samples are optional.

05.

Mass Production

Automated production, 100% QC, batch traceability.

06.

On-time Delivery & After-sales

Global logistics, complete compliance documents, and continuous supply.

Sample Request

Please send us your design drawings to start the sample process

Learn More From

Get a Free Sample Quote

1.Your company type

2.What industry products are your packaging materials used in?

3.Confirm the material, color, printing, logo, surface treatment, insert structure & quantity

4.What is your expected delivery time

5.Please provide us with your company name, phone number, and email address

6.Our cooperation process:Sample → Production → Delivery

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 3-7 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.

Why Choose Anitarpak

Where We Build Your Visions

· One-stop Labeling + Container Solution

We handle both the bottle and the label — ensuring perfect fit and alignment.

· Compatibility Testing

All label adhesives are tested for resistance to oil, alcohol, and moisture, ensuring long-term performance.

· Low MOQ & Fast Lead Time

Start from just 1000 pcs, with sample confirmation in 7 days.

· Design-to-Production Support

Our in-house design team provides layout adjustment, dieline creation, and color proofing.

· Eco-Friendly Label Options

Available in recyclable paper, biodegradable film, and soy-based ink printing.