A Complete Cost Breakdown, Packaging Guide & Supplier Strategy for Brands

Private label supplements have become one of the fastest-growing segments in the global health and wellness industry. From vitamins and protein powders to herbal extracts and functional nutrition products, brands of all sizes—from startups to established companies—are entering the market through private labeling.

But one of the most common and critical questions brand owners ask is:

How much does it actually cost to private label supplements?

The short answer: it depends.

The long answer—and the one that truly helps you make profitable decisions—requires a detailed breakdown of product formulation, packaging, labeling, compliance, logistics, and branding strategy.

In this article, we’ll walk you through a complete, transparent cost analysis of private label supplements, explain where your budget really goes, and show how smart packaging and labeling decisions can significantly reduce risk while increasing brand value.

Table of Contents

What Is Private Label Supplement Manufacturing?

Average Cost to Private Label Supplements (Quick Overview)

Core Cost Components Explained

Supplement Packaging Costs (Bottles, Pouches & Containers)

Private Label & Labeling Costs (Paper Labels, Shrink Sleeves, Vinyl Labels)

Regulatory, Compliance & Testing Costs

MOQ, Inventory & Cash Flow Considerations

How Packaging Choices Affect Total Cost & Brand Value

Cost-Saving Strategies Without Sacrificing Quality

Why Packaging & Label Suppliers Matter More Than You Think

How We Support Private Label Supplement Brands

Final Cost Summary & Next Steps

1. What Is Private Label Supplement Manufacturing?

Private label supplements are ready-made or semi-custom formulations produced by a manufacturer and sold under your own brand name. Instead of investing heavily in R&D and factory infrastructure, brands focus on:

Market positioning

Branding & packaging

Distribution & marketing

Your product differentiation often comes not from the formula itself—but from packaging, labeling, compliance clarity, and brand presentation.

This is where cost control and smart supplier selection become critical.

2. Average Cost to Private Label Supplements (Quick Overview)

While costs vary widely by product type and region, here is a general reference range:

| Cost Category | Estimated Range |

| Supplement Manufacturing | $0.05 – $0.50 per unit |

| Packaging (Bottle / Pouch) | $0.10 – $0.60 per unit |

| Label Printing | $0.05 – $0.25 per unit |

| Outer Packaging (Box) | $0.15 – $1.20 per unit |

| Testing & Compliance | $500 – $5,000+ (one-time) |

| MOQ Investment | $3,000 – $50,000+ |

👉 Packaging & labeling alone often account for 30–50% of the total product cost, especially for premium or retail-focused brands.

3. Core Cost Components Explained

Supplement Formula & Manufacturing

Factors affecting cost:

Type of supplement (capsules, tablets, powders, gummies)

Ingredient sourcing (synthetic vs natural)

Custom vs stock formula

Production location

This cost is usually fixed per unit, but packaging is where brands have the most flexibility.

4. Supplement Packaging Costs

Bottles, Jars & Pouches

Packaging is not just a container—it impacts compliance, shelf life, logistics, and consumer trust.

Common Packaging Options:

Plastic Bottles (HDPE / PET) – Most common, cost-effective

Glass Bottles – Premium look, higher cost, heavier shipping

Pouch Bags (Stand-up / High-barrier) – Lightweight, flexible MOQ

Bulk Jars / Canisters – Protein powders & sports nutrition

Typical Packaging Cost Ranges:

Plastic bottle: $0.10 – $0.35

Glass bottle: $0.30 – $0.80

High-barrier pouch: $0.12 – $0.50

👉 Choosing the wrong packaging can increase logistics cost by 20–40%.

5. Private Label & Labeling Costs

Labels are where compliance meets branding.

Label Types & Cost Impact:

Paper Labels – Cost-effective, ideal for dry environments

Vinyl / PET Labels – Waterproof, durable, premium feel

Shrink Sleeve Labels – Full-body branding, higher tooling cost

Label costs depend on:

Size & shape

Material

Printing method (digital vs gravure)

Color coverage

MOQ

Typical cost: $0.05 – $0.25 per unit

👉 Poor label material selection often leads to regulatory issues or product recalls.

6. Regulatory, Compliance & Testing Costs

Compliance is non-negotiable in the supplement industry.

Common costs include:

FDA label review (US market)

Nutrition facts formatting

Stability testing

Heavy metal & microbiological testing

Country-specific compliance (EU, Middle East, Asia)

Estimated cost:

$500 – $5,000+ per SKU

Smart packaging and clear labeling reduce rework and approval delays.

7. MOQ, Inventory & Cash Flow Considerations

MOQs affect cost per unit dramatically.

| MOQ Level | Risk | Unit Cost |

| Low MOQ | Low inventory risk | Higher unit cost |

| High MOQ | Higher upfront investment | Lower unit cost |

Packaging suppliers that support small-batch customization help brands scale safely.

8. How Packaging Choices Affect Total Cost & Brand Value

Many brands underestimate how much packaging affects:

Perceived product value

Retail acceptance

Online conversion rates

Repeat purchases

A $0.20 increase in packaging cost can often justify a $5–$10 retail price increase.

9. Cost-Saving Strategies Without Sacrificing Quality

Use digital printing for early-stage brands

Standardize bottle shapes

Modular packaging designs

Combine labels + boxes from one supplier

Optimize pallet & carton structure

10. Why Packaging & Label Suppliers Matter More Than You Think

Your packaging supplier impacts:

Speed to market

Compliance accuracy

Inventory flexibility

Brand consistency

A reliable supplier is not just a vendor—but a brand partner.

11. How We Support Private Label Supplement Brands

We specialize in private label packaging & labeling solutions for supplement brands, including:

Supplement bottles & high-barrier pouch bags

FDA-compliant label materials

Paper labels, vinyl labels & shrink sleeves

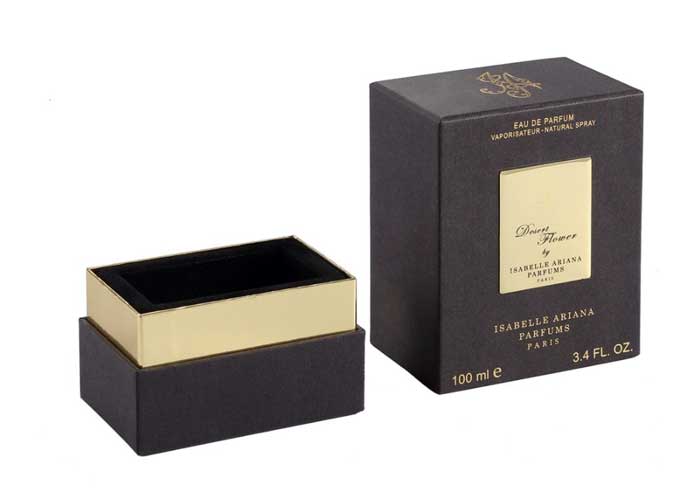

Custom outer boxes & gift packaging

Low MOQ sampling & fast prototyping

One-stop packaging coordination

We help brands:

Reduce packaging cost

Improve compliance accuracy

Launch faster

Scale with confidence

12. Final Cost Summary & Next Steps

Typical Private Label Supplement Startup Budget:

Entry-level brand: $5,000 – $10,000

Growing brand: $15,000 – $50,000

Premium retail brand: $50,000+

The biggest mistake brands make is focusing only on manufacturing cost, while ignoring packaging strategy.

If you’re planning to private label supplements, the smartest next step is to:

Validate your packaging concept

Request samples

Optimize cost structure early

Sample Request

Please send us your design drawings to start the sample process

Learn More From

Get a Free Sample Quote

1.Your company type

2.What industry products are your packaging materials used in?

3.Confirm the material, color, printing, logo, surface treatment, insert structure & quantity

4.What is your expected delivery time

5.Please provide us with your company name, phone number, and email address

6.Our cooperation process:Sample → Production → Delivery

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 3-7 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.