Integrated Packaging Manufacturing with Precision, Speed & Compliance

Premium Packaging Factory & Capabilities

From design engineering to mass production, Anitar is built to support complex custom packaging projects with stable quality and fast delivery.

Build Your Dream

25 Years Of Undefeated Success

With an experienced engineering, sales, and service team, we offer strong capabilities in independent design and innovation. Our production workshop meets national purification standards and is certified at the 100,000-level cleanroom standard.

Our products are widely used in the cosmetics, chemical, and food industries. Over the years, we have earned a solid reputation for consistent quality, reliability, and customer trust.

60,000,000+ units

Annual production capacity

30+ Designs

New product development speed

100% inspection

Before shipment compliant with FDA, EU, and ISO standards

1,200+ projects

Completed in 40+ countries

Production Process: From Material to Market

At Anitarpak, every packaging product is manufactured through a precise and standardized process — ensuring accuracy, quality consistency, and timely delivery.

We control every step in-house, from raw material input to finished product packaging, guaranteeing that every bottle and jar meets international standards.

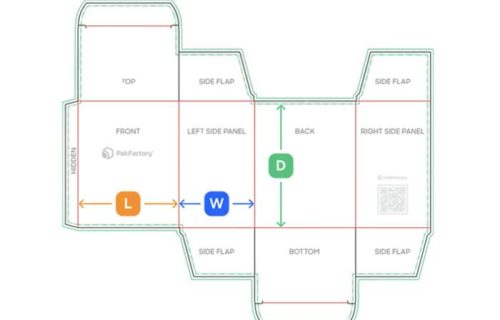

1. Packaging Engineering & Structure Development

💡 We not only produce, but also excel in engineering customization

- Box structure development (folding box/magnetic suction box/drawer box)

- Bag structure optimization (Stand up/Flat/Zipper/Spout)

- Load bearing and stacking test

- Suggestions for Transportation Stability and Cost Optimization

2. Material Processing Capabilities

🔧We can process products made of various materials

Our experienced technicians perform:

- Paper-based Packaging: Art paper / Kraft paper / Specialty paper

- Flexible Packaging Materials: PET / PE / BOPP / CPP / Aluminum foil

- Label Materials: Paper label / PET / PP / Vinyl

3. Advanced Printing Capabilities

🧴 High-speed, automated machines ensure uniform wall thickness and perfect surface finish. The heated material is injected or blown into molds, forming the body of bottles and jars.

We utilize:

- Digital Printing / Offset Printing/ Gravure Printing / Flexographic Printing

- Printing Accuracy: Color tolerance: ΔE ≤ 2, Registration accuracy: ±0.1 mm

4.Quality Control System

📊 All inspection data are recorded digitally for traceability. Quality is controlled throughout the production line, not just at the end.

- Incoming Material Inspection: Paper weight/film thickness

- In-Process Quality Control:Printing register/color consistency/film fastness

- Final Inspection Before Shipment:Size and Structure/Function Testing (Zipper, Handle, Tear)

5. Surface Decoration(Coating, Printing & Labeling)

🎨 We combine art and precision to create packaging that enhances your brand’s image. To match each brand’s identity, we provide various surface finishing and printing options:

- Injection molding for high-precision components (caps, acrylic jars)

- Blow molding for lightweight and large-volume bottles

- Glass molding for perfume and skincare packaging

6. Compliance & Certifications

✅ Only approved products proceed to the packing stage. Before shipment, every production batch undergoes a comprehensive final inspection:

- FDA-compliant materials (Food-grade)

- EU food contact standards

- FSC (paper options)

- ISO-based quality management

7. Sample & Prototyping Capabilities

🚢 Every shipment includes full documentation — packing list, QC report, and CO if needed. Finished products are carefully packed to ensure safe delivery worldwide:

- Digital proof: Same day

- White sample: 24–48 hours

- Printed sample: 3–5 working days

- Rapid prototyping for multi-SKU projects

3–5 million pcs

Paper Box Monthly Capacity

10+ million pcs

Labels Monthly Capacity

2 million pcs

Paper Bags Monthly Capacity

1–2 million pcs

Pouch Bags Monthly Capacity

Watch Our Factory in Action

Step inside Anitarpak’s modern manufacturing facility and see how your packaging ideas come to life.

From precision mold installation to high-speed injection and blow molding, from meticulous in-line inspection to flawless printing and coating — every detail is executed with care and expertise.

Duis aute irure dolor in reprehenderit velit.

Our factory video gives you a transparent view of our end-to-end production process, showing how we ensure quality, efficiency, and innovation at every stage.

We Provide the Best Service in Industry

Add a line that tells users how easily they can get in touch with you

Sample Request

Please send us your design drawings to start the sample process

Learn More From

Get a Free Sample Quote

1.Your company type

2.What industry products are your packaging materials used in?

3.Confirm the capacity, color, surface treatment process, quantity, and customized packaging requirements of the container

4.What is your expected delivery time

5.Please provide us with your company name, phone number, and email address

6.Our cooperation process:Sample → Production → Delivery

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 15–25 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.