Practical Strategies for Custom Packaging in Cosmetic, Food, and Supplement Brands

Packaging is more than just a container—it is a key touchpoint for brand perception, consumer trust, and product differentiation. Yet, for many brands, packaging accounts for 30–50% of total product cost, and reducing this cost seems to risk brand prestige or perceived quality.

The good news: with the right strategy, brands can reduce packaging cost while maintaining or even enhancing brand value.

In this article, we provide a step-by-step guide for cost optimization, from material selection to structural design, printing technology, and supply chain strategies.

Table of Contents

Why Packaging Cost Optimization Matters

Understanding the Balance Between Cost and Brand Value

Material Selection Strategies

Structural & Engineering Optimization

Printing & Decoration Techniques for Cost Efficiency

Leveraging Standardization Without Losing Uniqueness

Supplier & Production Strategies to Reduce Cost

Sustainable Packaging as a Cost-Saving Strategy

How a One-Stop Packaging Partner Helps Brands Optimize Cost

Action Plan & Next Steps

1. Why Packaging Cost Optimization Matters

High packaging cost can impact:

Profit margins: Reducing cost by 10–20% per unit scales across thousands of units.

Pricing strategy: Lower cost allows competitive retail pricing.

Startup feasibility: Smaller brands can launch with limited budgets.

Scalability: Efficient packaging supports multiple SKUs or seasonal variations.

At the same time, cutting corners in materials, finishing, or design can diminish brand perception, negatively affecting sales.

The challenge is maximizing efficiency while maintaining premium quality and brand identity.

2. Understanding the Balance Between Cost and Brand Value

Brand value is influenced by:

Material quality and finish

Structural integrity and usability

Visual appeal and decoration

Packaging consistency across SKUs

Reducing cost does not mean using cheap materials—it means making intelligent design and supply chain choices.

3. Material Selection Strategies

Materials often account for 40–60% of the packaging cost. Smart selection can reduce costs without sacrificing quality.

Paper Boxes

Use FSC-certified or recyclable cardboard with optimal thickness

Consider Kraft paper or SBS board for cost-effective yet premium feel

Avoid overly thick boards where unnecessary

Labels

Paper labels for dry products

Vinyl or PET for wet environments

Use removable adhesives for flexibility

Flexible Packaging / Pouches

Mono-material pouches reduce material cost and improve recyclability

High-barrier films protect product while being lightweight

Using the right material ensures quality perception while avoiding excess cost.

4. Structural & Engineering Optimization

Packaging structure heavily affects cost:

Reduce waste through optimized die-cut layout

Use modular designs to allow multiple SKUs to share one template

Avoid over-engineered internal trays unless necessary

Ensure stability and protection while using minimal material

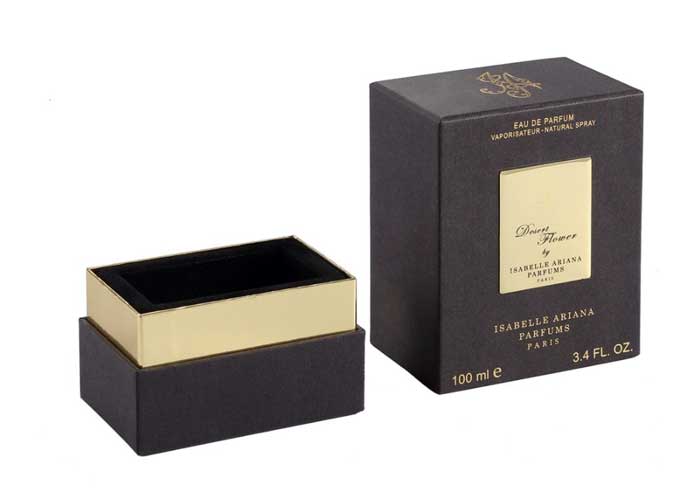

Example: A drawer-style cosmetic box can maintain premium feel with 50% less cardboard by optimizing inner tray geometry.

5. Printing & Decoration Techniques for Cost Efficiency

Printing and decoration are key cost drivers:

Digital printing: Lower MOQ, ideal for startups or seasonal SKUs

Offset printing: Efficient for large batches, high setup cost

Selective finishing: Spot UV, embossing, hot stamping only on logo or highlights

Minimalist design: Fewer colors reduce ink and plate costs

Combining high-impact visual elements with minimalist printing can maintain brand prestige while reducing cost.

6. Leveraging Standardization Without Losing Uniqueness

Use standard box sizes or shared molds across multiple SKUs

Customize surface finishing, labels, or inserts for differentiation

Standardization reduces tooling cost, setup time, and material waste

This strategy allows low-cost production with distinctive branding elements.

7. Supplier & Production Strategies to Reduce Cost

Consolidate suppliers: One partner for boxes + labels reduces logistics costs

Negotiate MOQ intelligently: Smaller batches with digital printing for testing, then scale up

Factory selection: Choose a supplier with integrated printing, cutting, and finishing

Transparent costing: Avoid hidden fees like plate fees, die charges, or shipping surcharges

Your packaging supplier should be a cost-optimization partner, not just a vendor.

8. Sustainable Packaging as a Cost-Saving Strategy

Eco-friendly choices can reduce both material cost and appeal to conscious consumers:

Recyclable materials can replace composite laminates

Lightweight boxes reduce shipping cost

Mono-material pouches simplify production

FSC-certified paper adds marketing value while being cost-effective

Sustainability is both a brand differentiator and a cost-saving approach.

9. How a One-Stop Packaging Partner Helps Brands Optimize Cost

Working with an integrated packaging partner like Anitarpak allows brands to:

Combine boxes, labels, pouches, and printing in one factory

Access low MOQ sampling and fast prototyping

Optimize structural, material, and finishing decisions

Maintain high quality and brand consistency

Cost reduction is achievable without compromising quality when design, material, and production are engineered together.

10. Action Plan & Next Steps

Brands looking to reduce packaging cost should:

Audit current packaging cost by material, printing, and structure

Identify high-cost areas with minimal brand impact

Explore digital printing or modular design options

Partner with a supplier offering low MOQ, integrated production, and compliance support

Test sample batches before committing to full production

Call to Action:

Request a cost optimization consultation

Get free paper box & label samples

Talk to a packaging engineer for a custom solution

Sample Request

Please send us your design drawings to start the sample process

Learn More From

Get a Free Sample Quote

1.Your company type

2.What industry products are your packaging materials used in?

3.Confirm the material, color, printing, logo, surface treatment, insert structure & quantity

4.What is your expected delivery time

5.Please provide us with your company name, phone number, and email address

6.Our cooperation process:Sample → Production → Delivery

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 3-7 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.